Manufacturing in Guizhou, Digital Transformation, Hu Ming: Add "Number" Development to Make Elevators Safer and Comfortable

2024-05-14

author:

Page view:

Manufacturing in Guizhou, Digital Transformation, Hu Ming: Add "Number" Development to Make Elevators Safer and Comfortable

Over the past ten years, AVIC elevator products have gradually gone out of Guizhou, southwest and international. Its operating income has also exceeded 0.56 billion yuan from 62.16 million yuan in 2011 to 2021, with an average annual growth rate of more than 28%, and has achieved remarkable results. How does the company promote the innovative development of intelligent manufacturing and promote the continuous improvement of production efficiency? In the wisdom of innovation, new in change, change in efficiency, today's digital transformation we talk about, the reporter interviewed the Guizhou AVIC Elevator Co., Ltd. Party Secretary, Chairman Hu Ming.

Reporter Chen Shanshan: Hello, Mr. Hu. AVIC Elevator is an established enterprise. When did we start the digital transformation?

Hu Ming, Secretary of the Party Committee and Chairman of Guizhou AVIC Elevator Co., Ltd.: We are an old military enterprise. In 2004, we responded to the call of the country to develop civilian products and became an elevator company. The state has put forward high requirements for intelligent manufacturing. Due to the site and equipment, our old factory has great problems in the production of modern elevators. In 2016, the company responded to the call of the Zunyi municipal government and carried out the "retreat from the city and enter the park". In full accordance with the requirements of the intelligent factory, adopting the all-digital design and production concept, the "retreat from the city and enter the park" was completed in 2018, and the factory has truly entered digital production.

Reporter Chen Shanshan: The average annual growth rate of AVIC Elevator's operating income has exceeded 28% in 10 years. We want to know how AVIC Elevator has maintained its rapid development?

Hu Ming, Secretary of the Party Committee and Chairman of Guizhou AVIC Elevator Co., Ltd.: From an old military factory to a modern civilian state-owned enterprise, several major difficulties have been encountered in the development process. Because the requirements of the military industry are very rigorous, its technological innovation includes the upgrading of products, which requires a very long cycle, while the development of civilian products must be market-oriented, requiring very fast and high-end, and time is efficiency. it is a completely different concept. In the end, we adopted a solution. The first is for senior executives and technical backbones to take shares in the company, and the second is to introduce a team of professional managers to check on us in terms of technical production, and to benefit from the government's support for us to "retreat from the city and enter the park.", Support from equipment and venues, these three aspects have enabled our company to develop and grow at a high speed in recent years. At present, we have become the enterprises with the largest local shipments in Guangxi, Yunnan, Sichuan, Chongqing and Guizhou provinces. Now we have become the top 30 in shipments among more than 460 elevator companies across the country, and we are expected to enter the top 20 this year in 2022. The company mainly has two products, one is elevator, accounting for 80% of our main business, and the other is high and low voltage power distribution accounting for 20%. Our 2/3 products are sold outside the province, and 1/3 products are sold in the province. Through the "the belt and road initiative" policy, we have sold to Kyrgyzstan, Kazakhstan and Oman.

Guizhou station reporter Chen Shanshan: What is the biggest advantage of AVIC Elevator? In the face of the impact of the epidemic, how did the company respond, and what digital transformation has been done?

Hu Ming, Secretary of the Party Committee and Chairman of Guizhou AVIC Elevator Co., Ltd.: Civil products require high precision and fast speed. In this case, it is completely manual production. There will be two problems. One is that the cost is too high, and the second is Quality is difficult to control.

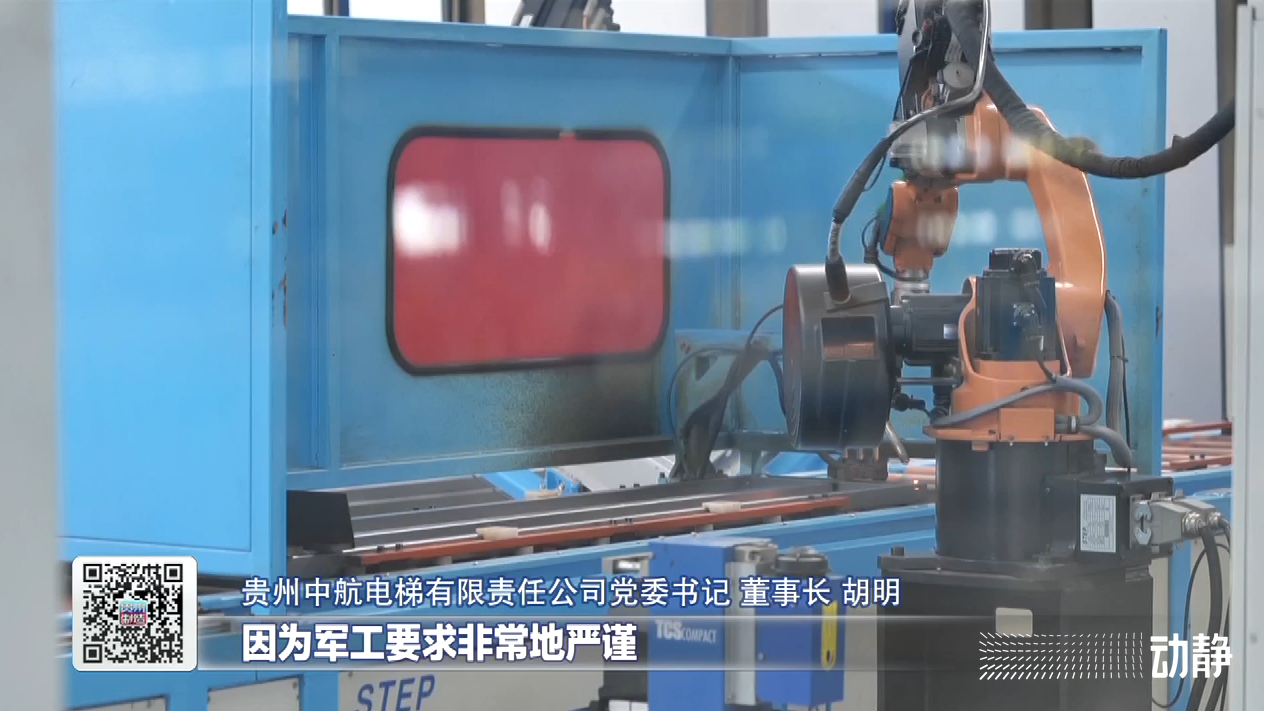

When building automated factories according to national requirements, we use robots to ensure product consistency. Under normal circumstances, people can only work in one shift 24 hours a day, and robots can work in three shifts. The whole robot is like an assembly line. There used to be 16 people. Now I only need one person. The efficiency improvement is very fast.

The intelligent factory first guarantees the quality of the products from the production, but there is a saying in our elevator industry: 3 points for manufacturing, 7 points for installation and later maintenance. In the early stage of the construction of intelligent factories, we took the post-service market as the back force for future growth and promotion, and vigorously developed the Internet of Things of elevators. Monitoring from the front end of elevator production, including installation and maintenance, can be comprehensively analyzed through elevator Internet of Things data.

As a state-owned enterprise, we do not maximize economic benefits. From the design concept of the source, we have made medium and long-term planning and positioning, so our products have been recognized by customers in China, especially in the Yangtze River Delta and the Pearl River Delta., Gradually through the "Belt and Road" out of the country, it has also received a relatively good evaluation abroad.

In the new crown epidemic, first of all, we in accordance with the national policy to grasp their own epidemic prevention, to ensure that the factory can be normal production. Second, on the product, we have developed touchless buttons, infrared buttons, voice control system and face recognition system to ensure that the elevator is not touched during operation. The air is purified in the car to ensure the cleanliness of the car, which is favored by many developers and customers. In the past two years, the sales of most elevator factories have shown a downward trend, and the growth rate of our elevators in the first half of this year was 80%. This is also our innovative efforts in product development, including after-sales service.

Reporter Chen Shanshan: Under the background of high-quality development, how does AVIC Elevator plan to transform and develop during the "14th Five-Year Plan" period?

Hu Ming, Secretary of the Party Committee and Chairman of Guizhou AVIC Elevator Co., Ltd.: One of our next development directions is that most elevators are generally at about 3 meters per second. Our company's 168-meter test tower will be completed immediately. After completion, it can produce 10-meter elevators per second, basically reaching the most cutting-edge elevator production. We have to do research and development from the entire life cycle of elevators, from elevator production to installation and maintenance, use data to ensure safe and comfortable elevator use. Second, we integrate elevators, high and low voltage power distribution, and three-dimensional garages into the intelligent community, and integrate these aspects to control them to ensure the normal operation of the intelligent community. After the 20th National Congress of the Communist Party of China, our company has set a higher goal. In the next step, we are going to build a completely modern manufacturing base, a brand-new intelligent factory, production mainframe, control cabinet, intelligent logistics, and supporting elevators, high and low voltage power distribution. This is the goal we plan to achieve during the 14th Five-Year Plan period.

The real economy is the foundation of the economy, and the digital economy is becoming a powerful driving force for the real economy. In 2021, the deep integration level of big data and the real economy in Guizhou Province reached 42.5, with steady growth for five consecutive years. Compared with 2020 and 2017, it increased by 3.4 and 25.7, respectively, with an average annual increase of 6.4 percentage points. Next, our reporters will continue to walk into Zhenhua Group, Aerospace Jiangnan, Guotai Liquor Industry and other enterprises to learn about the stories of enterprises in promoting the innovation and development of intelligent manufacturing upgrades, industrial software applications and system solutions. Welcome to lock in Tuesday's Made in Guizhou.

Source: Guizhou

If there is infringement, contact Li delete

Keywords:

AVIC Elevator Equipment, AVIC Elevator, Elevator Sales, AVIC Elevator Sales, Elevator Maintenance